NOW Data

NOW Data is a groundbreaking cloud-based platform designed for owners and operators of refrigeration systems. In the continuing evolvement of AI and machine learning, we have developed the “deep-seek” lowest-cost data ingestion and decision-making control platform in the world. Development began in the summer of 2024, and we are thrilled to announce that Costco is our very first customer. They have now adopted NOW Data to support its business operations in reducing energy consumption, emissions, and trading risks associated with temperature-controlled systems.

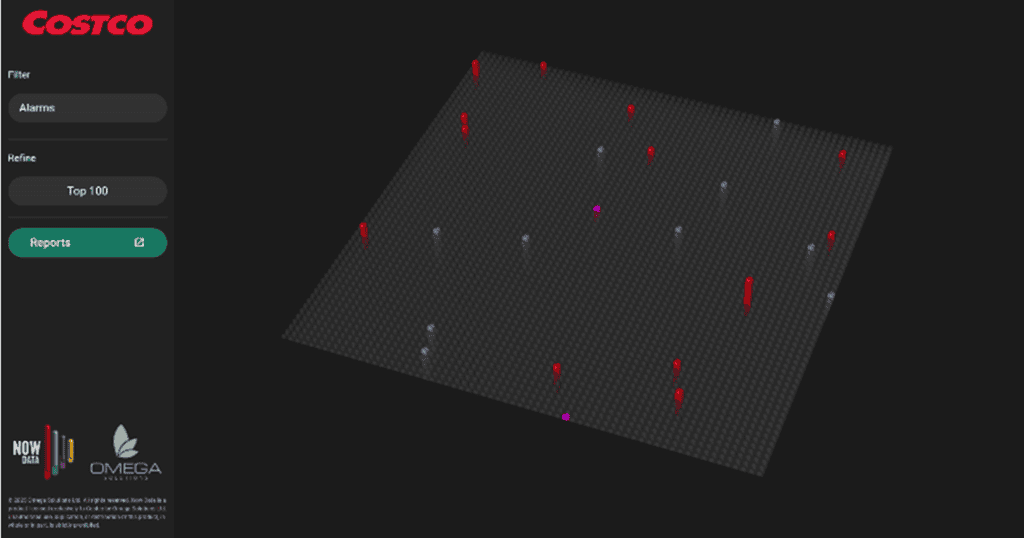

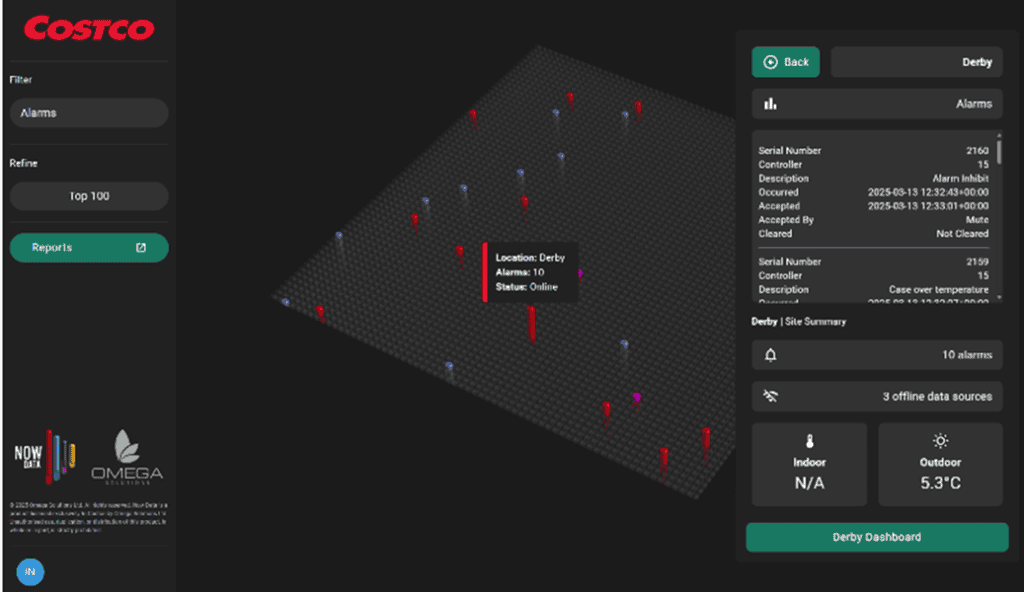

Our modus operandi was to create an intuitive platform that provided an unparalleled and addictive user experience. Costco’s refrigeration data, displayed in real-time across all their stores on an enticing dashboard, is available at the touch of a button.

About NOW Data

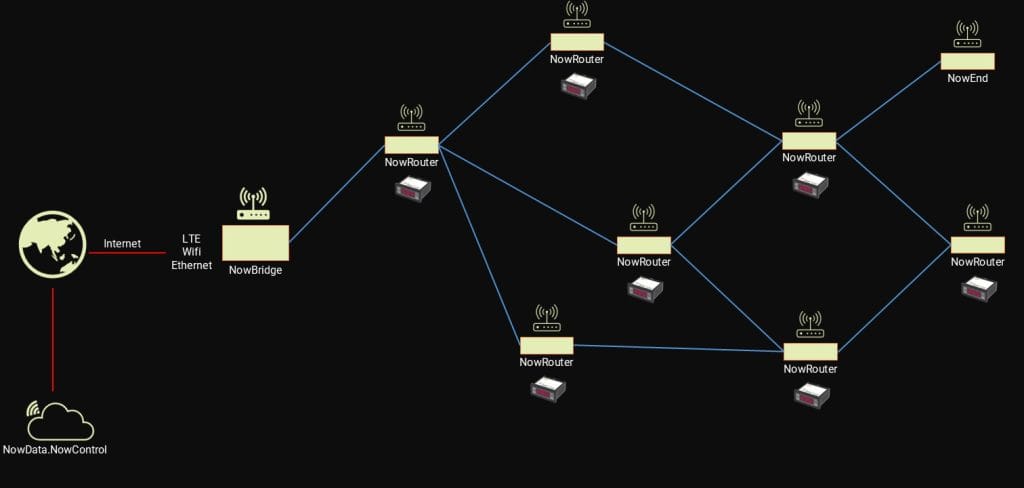

At its core, NOW Data is a cloud-based data harvesting platform. It ingests information from individual stores’ BMS systems, covering all remotely connected and controlled assets, that sends real-time outputs to the NOW Data platform and our UX dashboard.

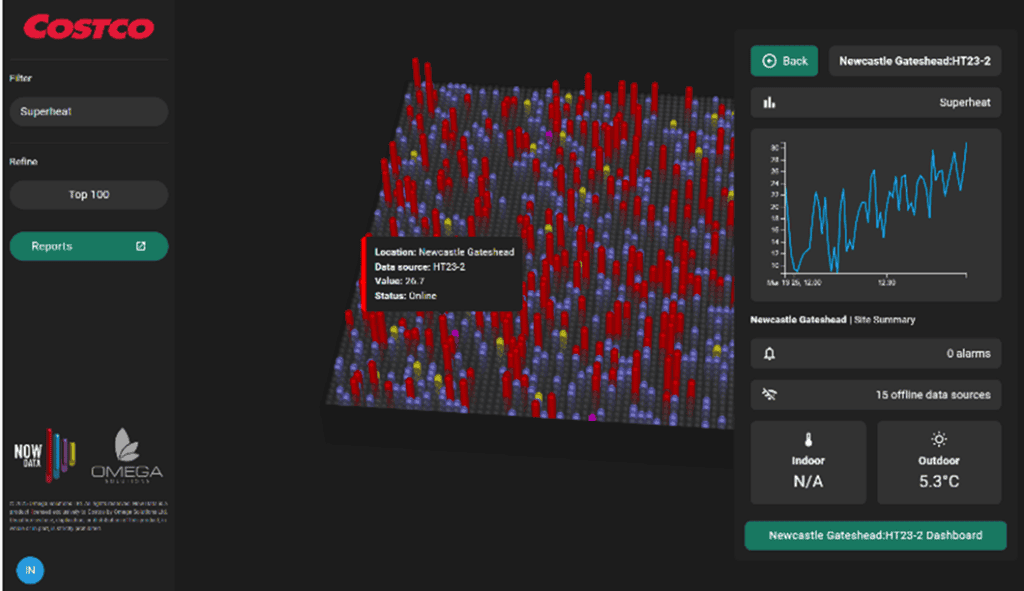

NOW Data visualises all refrigeration values and settings of a device over a predetermined period to see what is happening. Its UI dashboard provides an exceptional experience of understanding operational problems across the estate without needing to dial into a single site or multiple sites, as is required with OEM remote monitoring systems.

NOW Data can connect to 24,000 sites and 1,200,000 devices, providing 72,000,000 data points!

NOW Data takes away operational concerns, including muting and accepting alarms on a BMS Front-End panel. The outputs generated and any subsequent action (service calls) are directly interrogated and managed by our team. Providing trading surety, compliance and uptime, NOW Data improves asset uptime by establishing concerns and preventing them from escalating into major problems. NOW Data ensures that food remains at the correct temperature at the lowest possible cost. Saving money and serving as an indispensable carbon-reducing tool, NOW Data reduces energy consumption and carbon emissions by identifying set-point parameter concerns in real time (e.g., controller setpoints differ from OEM parameters).

What we found at Costco

What was immediately apparent was the high-level alarms, variation of alarm parameters and the associated compliance issues. Nuisance alarms occur daily, wasting warehouse employees’ time and causing frustration, with the risk of muting significant alarms. Example alarms included high superheats, product temperatures, air-on and air-off temperatures, as well as low suction and high discharge pressures, all of which are now being managed through the adoption of NOW Data.

Inconsistent data proved to be a challenge, as it often is with any business that relies on individual Building Management System (BMS) systems, where refrigeration controller parameters can be changed outside of specification and where issues can be masked while increasing energy use. NOW Data standardises all data, consistently enabling a better, consistent and standard approach to control. The output from NOW Data within our dashboard ensures that clean data is returned in a unified manner from all assets across all stores, enabling a consistent visual experience. Effectively, we transform raw data into tangible insights and produce real-time reports that Costco and its partners utilise to make informed decisions and drive improvements.

NOW Act

Through the use of rules-based algorithms and our extensive experience, data provided by NOW Data intelligently identifies what requires attention via NOW Act. Our NOW Control platform then automatically makes any necessary adjustments.

NOW Control

With NOW Control, when connectivity is unavailable, our development includes a low-cost controller. Working with OEMs, we are developing IoT gateways to connect our customers and enable them to fully leverage the benefits of the NOW Data platform. Back to NOW Act, our data management and controller development is the true definition of machine learning. By linking NOW Data with NOW Act and NOW Control, we will have the ability to automatically adjust setpoints based on rule-based algorithms in conjunction with our NOW Bridge and NOW Router technologies. This not only helps maintain compliance and uptime but also reduces energy consumption and the number of callouts and faults that service engineers must deal with.

Why NOW Data?

Operational Support

- NOW Data takes away operational concerns, including muting and accepting alarms on a front-end panel. The outputs generated and any subsequent action (service calls) can be directly interrogated and managed by OMEGA Solutions.

Trading Surety & Compliance

- NOW Data enhances asset uptime by identifying issues and preventing them from escalating into major problems. NOW Data also ensures compliance (e.g., products being maintained at the correct temperature).

Energy & Emissions

- NOW Data can reduce energy consumption and carbon emissions by identifying set point parameter concerns in real-time (e.g., controller setpoints differ from OEM parameters).